Air classifier manufacturer reveals: Core technology of ultrafine powder processing

Published Time:

2025-03-09 09:00

Source:

Airflow Classifier Manufacturers Reveal: Core Technology for Ultrafine Powder Processing

In modern industry, the processing and application of ultrafine powders are increasingly valued. Various industries, such as pharmaceuticals, food, and chemicals, have strict requirements for the particle size, purity, and distribution of powders. Airflow classifiers, these amazing devices, are one of the core technologies to achieve these requirements. So, how do airflow classifier manufacturers master these technologies? Today, let's explore this.

The Principle of Airflow Classifiers

First, what is an airflow classifier? Simply put, it is a device that uses the kinetic energy of airflow to classify powders. Imagine you gently throw some feathers next to a rotating fan. With the flow of the wind, the feathers will be carried into the air, while heavier substances will remain on the ground. The principle of the airflow classifier is like this simple experiment: by controlling the speed of the airflow, powders of different particle sizes are separated.

The main function of this equipment is to classify raw material powders, allowing particles of different sizes to achieve efficient separation in the same process. This not only improves production efficiency but also ensures product consistency and high purity. Therefore, airflow classifier manufacturers must be proficient in gas dynamics and powder engineering when designing and manufacturing these devices to ensure the efficiency and stability of the equipment.

Key Technologies of Airflow Classifiers

Next, let's look at the core breakthroughs of airflow classifier manufacturers in this technology. First is the control of airflow. By precisely adjusting the speed and direction of the airflow, the classification of particles can be effectively achieved. This requires high-precision sensors and control systems to ensure the stability of the airflow. In this aspect, some advanced airflow classifier manufacturers have achieved automated control, making the classification process more intelligent.

Then there is the design of the classification chamber. The shape, size, and internal structure of the classification chamber will directly affect the classification effect. Imagine that if the design of a stadium track is unreasonable, it will be difficult for athletes to perform at their best. Airflow classifier manufacturers continuously optimize the design of the classification chamber to adapt to different types of materials, ensuring that each particle can achieve the best separation effect.

Finally, cleaning and maintenance cannot be ignored. This is an important factor related to the long-term stable operation of the airflow classifier. Because during the processing, powders may adhere to the inner walls of the equipment, affecting subsequent production. Therefore, airflow classifier manufacturers usually consider easy-to-clean features in equipment design to reduce maintenance costs and improve production efficiency.

Application Areas of Airflow Classifiers

Speaking of this, you may be curious about where airflow classifiers are used. In fact, its application range is very wide. In the pharmaceutical industry, airflow classifiers can help produce uniformly sized drugs, improving efficacy. In the food industry, it can ensure the uniformity of food powders, enhancing taste. In the chemical industry, airflow classifiers can help produce higher-quality coatings and plastics.

Conclusion

In general, airflow classifier manufacturers, by mastering gas dynamics, equipment design, and maintenance technologies, have driven the progress of ultrafine powder processing. In the future, with the continuous development of technology, we can expect the emergence of more efficient and intelligent airflow classifiers. All industries will benefit from this.

Related News

How do air classifier manufacturers meet the needs of different industries?

This article reveals how air classifier manufacturers flexibly meet the needs of different industries, and explores the importance of technological innovation and customer communication. Let's focus on the future development of this field together, and choose the most suitable solution for your business.

Recommended manufacturers of the most popular airflow classifiers in the industry

When searching for airflow classifier manufacturers, it is crucial to understand the popular brands, technical capabilities, and after-sales service in the market. This article recommends some manufacturers worth your attention to help you make an informed choice.

Air classifier manufacturer reveals: Core technology of ultrafine powder processing

In this article, we reveal the core technologies of airflow classifier manufacturers and explore the mysteries of ultrafine powder processing. By gaining a deep understanding of the principles, key technologies, and application fields of airflow classifiers, we hope to help you better understand the value and role of this important equipment.

How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Selecting the right air classifier manufacturer is crucial for the quality of powder processing. Understanding the manufacturer's qualifications, product quality, and customer feedback ensures proper equipment configuration and maintenance, achieving optimal processing results. Let's explore how to find the best partners in the market!

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, the quality of powder materials is crucial. Airflow pulverizers, with their highly efficient pulverization capabilities and excellent particle uniformity, have become key equipment for improving powder quality. This article will delve into the working principles, advantages, and important applications of airflow pulverizers in powder production.

Comparative Analysis of Airflow Mills and Traditional Mills

For industries requiring high-efficiency and high-quality pulverization, air flow pulverizers are a better choice, while traditional pulverizers have their unique advantages in terms of applicability and economy. Understanding the differences between the two will help you choose pulverizing equipment more easily!

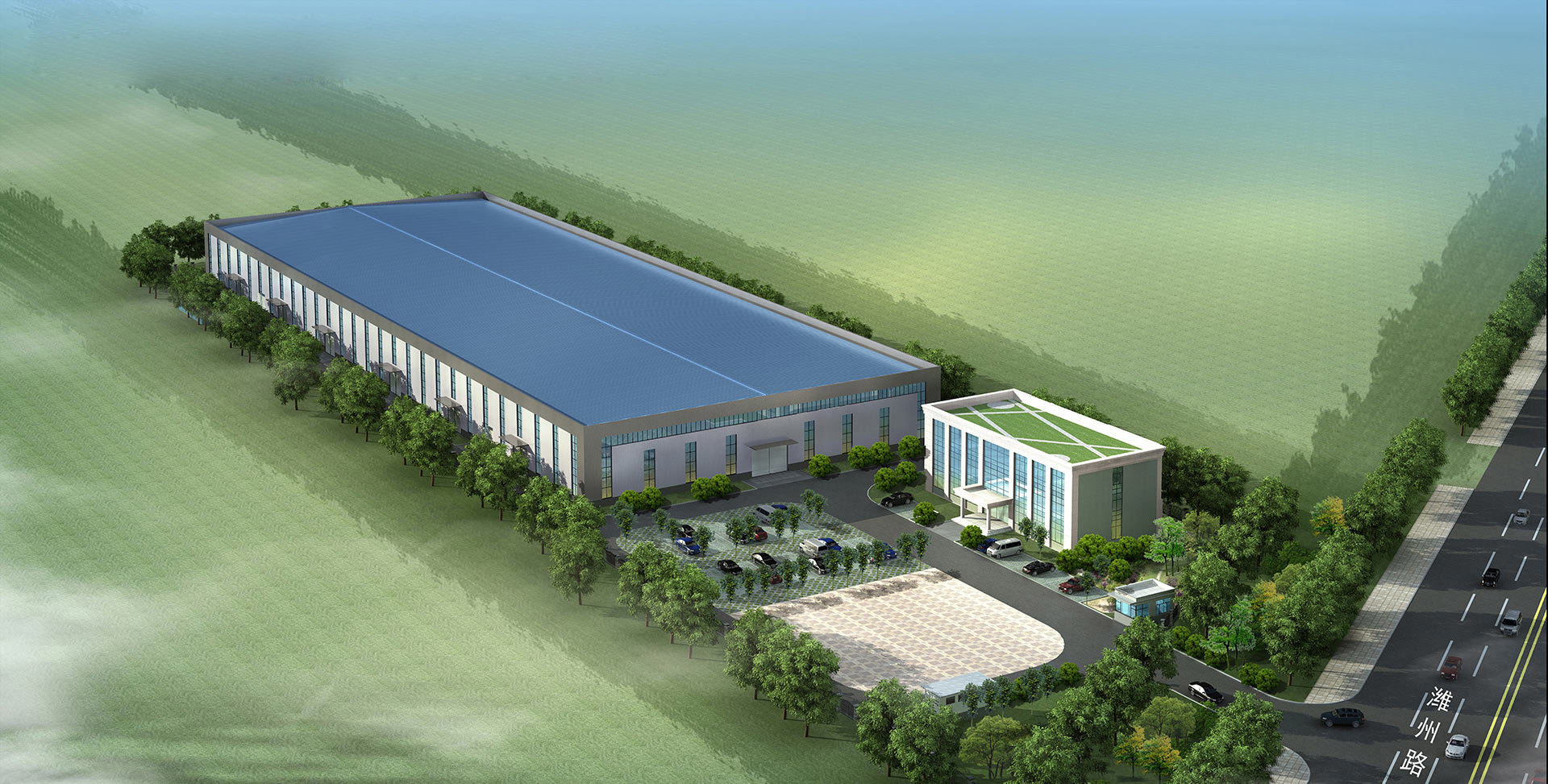

Shandong Jietemu Powder Technology Equipment Co., Ltd.

Address:500 meters northwest of the intersection of National Highway 206 and Beihai Road, Fangzi District, Weifang City, Shandong Province