Comparative Analysis of Airflow Mills and Traditional Mills

Published Time:

2025-02-19 09:00

Source:

Difference Analysis between Airflow Pulverizer and Traditional Pulverizer

In the field of industrial pulverization, airflow pulverizers and traditional pulverizers each have their own advantages. Choosing the right equipment is crucial for production efficiency and product quality. This article will provide a detailed analysis of the differences between these two types of pulverizers to help you find the most suitable pulverization solution among many options.

What is an airflow pulverizer?

An airflow pulverizer is an advanced pulverizing equipment that uses high-pressure airflow to pulverize materials. Through the powerful force of air, the materials, under the action of the airflow, collide with other materials or equipment walls at a very high speed, thus achieving pulverization. Simply put, an airflow pulverizer is like a "dance of air," where materials continuously collide and grind under the guidance of air, ultimately achieving a fine powder effect.

Characteristics of Traditional Pulverizers

Compared with airflow pulverizers, traditional pulverizers usually rely on mechanical force to break down materials. Their working principle is similar to that of a "striker," gradually turning materials into powder through hammering and grinding. These devices usually have a simple structure and are easy to maintain, but they are often inferior to airflow pulverizers in terms of pulverization efficiency and powder uniformity. Imagine that a traditional pulverizer is like using a hammer to hit a stone; although it can be broken, there are always some rough and uneven residues.

Advantages of Airflow Pulverizers

The biggest advantage of airflow pulverizers lies in their efficient and fine pulverization capabilities. Due to the high-speed action of the airflow, the materials are pulverized to the micron level almost instantaneously, and the particle size distribution of the powder is relatively uniform. In addition, the airflow pulverization process does not generate excessive heat, which is especially important for some heat-sensitive materials, avoiding the quality degradation of the materials due to temperature increase during pulverization.

Limitations of Traditional Pulverizers

Although traditional pulverizers are still popular in some industries, they have some obvious limitations. For example, heat is easily generated during pulverization, which may affect the properties of some materials. In addition, due to the limitations of the pulverization method, traditional pulverizers are inefficient in processing materials with high hardness and may require multiple pulverizations to achieve the desired effect.

Differences in Applicable Scope

Airflow pulverizers are suitable for high-requirement pulverization work, such as in the pharmaceutical, food, and chemical industries. These fields usually have extremely high requirements for the purity and fineness of the powder, which airflow pulverizers can easily meet. At the same time, due to their efficient pulverization capabilities, they can significantly improve production efficiency. Traditional pulverizers are mostly used in industries with less stringent powder requirements, such as building materials and ores. Although the efficiency is relatively low, the equipment cost is low and the maintenance is simple.

Economy and Return on Investment

From an economic point of view, the initial investment in airflow pulverizers is relatively high, but their efficient production capacity can recoup the cost in a short period of time. Although traditional pulverizers have lower equipment investment, in long-term operation, due to factors such as low pulverization efficiency and high energy consumption, they may lead to higher operating costs. Therefore, when choosing equipment, enterprises should combine their own production needs and budget to comprehensively evaluate the return on investment.

Summary and Suggestions

In general, airflow pulverizers and traditional pulverizers have significant differences in working principles, pulverization effects, and applicable scopes. When choosing pulverizing equipment, enterprises should first clarify their own needs. If you pursue high-efficiency and high-quality products, an airflow pulverizer is undoubtedly an excellent choice. If your budget is limited and your powder requirements are not particularly high, a traditional pulverizer is also a feasible option. Remember, choosing equipment is like choosing tools; the right one is the best!

I hope this analysis of airflow pulverizers and traditional pulverizers can help you make a wiser choice!

Related News

How do air classifier manufacturers meet the needs of different industries?

This article reveals how air classifier manufacturers flexibly meet the needs of different industries, and explores the importance of technological innovation and customer communication. Let's focus on the future development of this field together, and choose the most suitable solution for your business.

Recommended manufacturers of the most popular airflow classifiers in the industry

When searching for airflow classifier manufacturers, it is crucial to understand the popular brands, technical capabilities, and after-sales service in the market. This article recommends some manufacturers worth your attention to help you make an informed choice.

Air classifier manufacturer reveals: Core technology of ultrafine powder processing

In this article, we reveal the core technologies of airflow classifier manufacturers and explore the mysteries of ultrafine powder processing. By gaining a deep understanding of the principles, key technologies, and application fields of airflow classifiers, we hope to help you better understand the value and role of this important equipment.

How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Selecting the right air classifier manufacturer is crucial for the quality of powder processing. Understanding the manufacturer's qualifications, product quality, and customer feedback ensures proper equipment configuration and maintenance, achieving optimal processing results. Let's explore how to find the best partners in the market!

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, the quality of powder materials is crucial. Airflow pulverizers, with their highly efficient pulverization capabilities and excellent particle uniformity, have become key equipment for improving powder quality. This article will delve into the working principles, advantages, and important applications of airflow pulverizers in powder production.

Comparative Analysis of Airflow Mills and Traditional Mills

For industries requiring high-efficiency and high-quality pulverization, air flow pulverizers are a better choice, while traditional pulverizers have their unique advantages in terms of applicability and economy. Understanding the differences between the two will help you choose pulverizing equipment more easily!

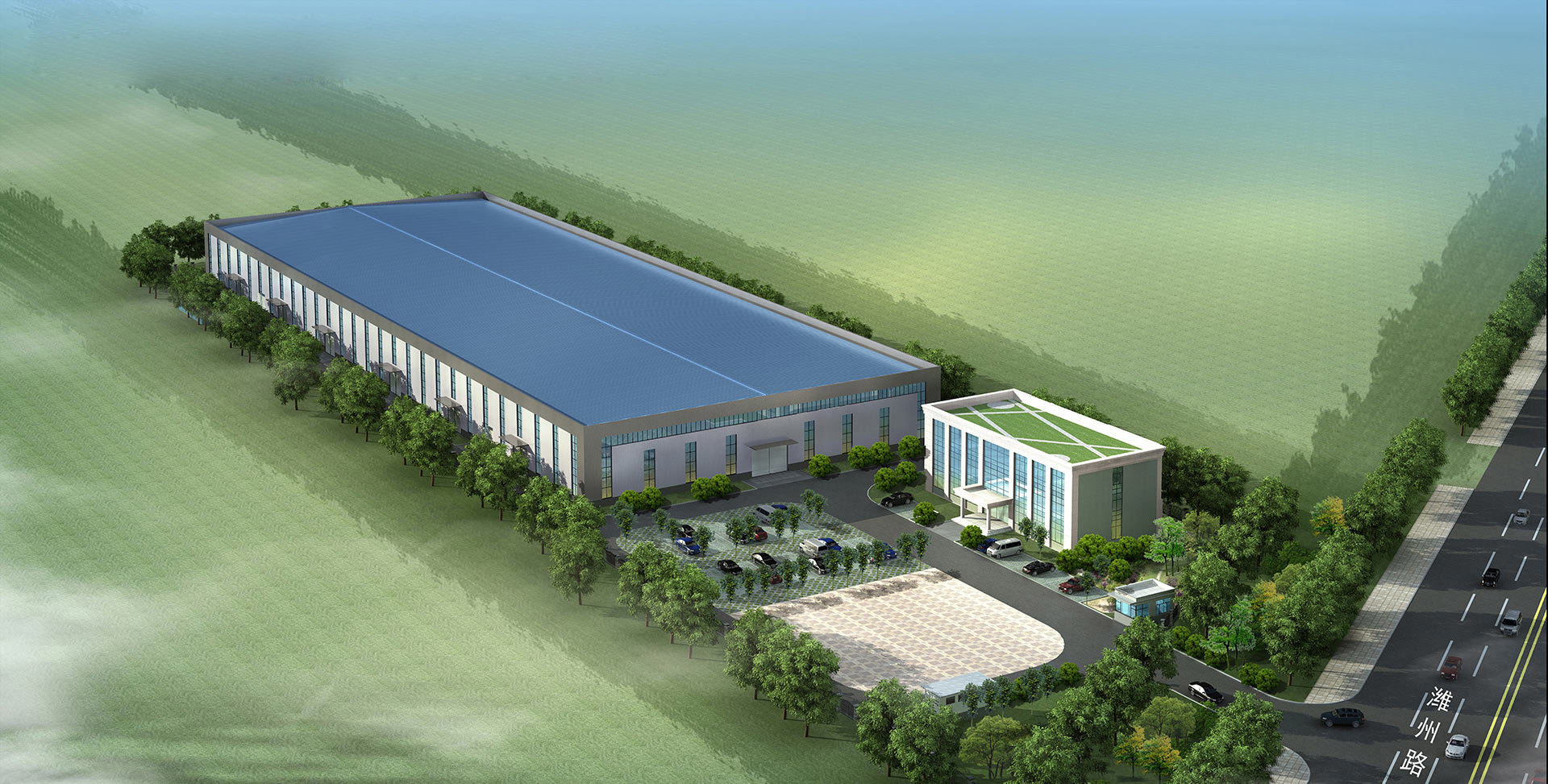

Shandong Jietemu Powder Technology Equipment Co., Ltd.

Address:500 meters northwest of the intersection of National Highway 206 and Beihai Road, Fangzi District, Weifang City, Shandong Province