How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Published Time:

2025-03-03 09:00

Source:

How to choose an air classifier manufacturer to ensure the quality of powder processing?

In the powder processing industry, the role of air classifiers is irreplaceable. You might wonder why choosing the right air classifier manufacturer is so important? It's like choosing a good chef to cook a delicious dinner; the choice of manufacturer directly affects the quality of the final product. Today, let's talk about how to choose an air classifier manufacturer to ensure the quality of your powder processing.

Understanding the working principle of air classifiers

Before we delve deeper, let's understand the basic principle of air classifiers. Simply put, air classifiers use airflow to separate powders of different particle sizes. This is like sifting sand; you want to separate the large and small particles clearly. The choice of manufacturer directly affects the performance of the air classifier and thus the classification effect of the powder.

The importance of choosing an air classifier manufacturer

If you enter the market and see a dazzling array of air classifier manufacturers, will you feel at a loss? Indeed, with the advancement of technology, more and more manufacturers have emerged, but not every manufacturer can provide high-quality products. Just as a good knife is important to a chef, choosing a reliable air classifier manufacturer is the first step in ensuring powder processing quality.

How to evaluate an air classifier manufacturer

So, how do you evaluate an air classifier manufacturer? We can consider it from several aspects.

1. Manufacturer's qualifications and experience

First, check the manufacturer's qualifications and experience. A manufacturer with many years of industry experience usually has a deeper understanding of the market and can provide solutions that better meet the needs. It's like you're unlikely to ask a newly debuted chef to prepare a grand banquet for you.

2. Product quality and technical support

Second, pay attention to product quality and technical support. Product quality directly affects processing efficiency and effect. Excellent manufacturers will not only provide high-quality air classifiers but also provide comprehensive technical support after sales. Imagine if you encounter problems during use, but the manufacturer cannot respond promptly; it would be a frustrating experience.

3. Customer feedback and reputation

In addition to the above two points, customer feedback and reputation are also key to evaluation. You can search for related comments online or ask friends who have used the manufacturer's equipment for advice. Just as when choosing a restaurant, we often refer to the reviews of other consumers, the same applies to manufacturers.

How to ensure the quality of powder processing

After choosing a suitable air classifier manufacturer, how can you further ensure the quality of powder processing? The following suggestions are for your reference:

1. Reasonable equipment configuration

Different powder characteristics require different processing equipment. Ensure that the equipment provided by the chosen manufacturer matches the processing needs. It's like you can't use a knife to chop bones; choosing the wrong tool will only complicate things.

2. Regular maintenance and upkeep

Regular maintenance and upkeep of equipment are also crucial. No matter how excellent your air classifier is, if it is not maintained for a long time, the final processing effect will be greatly reduced. Just like a car, it needs regular maintenance to maintain its optimal condition.

3. Continuous learning and improvement

Finally, maintaining attention to and learning about the industry is a long-term plan to ensure processing quality. The market is constantly changing, with new technologies and new materials emerging endlessly. As business owners, if you do not keep up with the times, you may be eliminated by the market.

Summary

Choosing an air classifier manufacturer is a crucial step that determines the quality of your powder processing. From the manufacturer's qualifications and product quality to customer feedback, all are essential elements that cannot be ignored. Ensuring reasonable equipment configuration, regular maintenance, and continuous learning are essential to maintaining processing quality.

In this competitive market, choosing an excellent air classifier manufacturer is like choosing a trustworthy partner that will significantly benefit your business. We hope that you can find the most suitable manufacturer among many choices, ensure the quality of powder processing, and achieve greater success!

Related News

How do air classifier manufacturers meet the needs of different industries?

This article reveals how air classifier manufacturers flexibly meet the needs of different industries, and explores the importance of technological innovation and customer communication. Let's focus on the future development of this field together, and choose the most suitable solution for your business.

Recommended manufacturers of the most popular airflow classifiers in the industry

When searching for airflow classifier manufacturers, it is crucial to understand the popular brands, technical capabilities, and after-sales service in the market. This article recommends some manufacturers worth your attention to help you make an informed choice.

Air classifier manufacturer reveals: Core technology of ultrafine powder processing

In this article, we reveal the core technologies of airflow classifier manufacturers and explore the mysteries of ultrafine powder processing. By gaining a deep understanding of the principles, key technologies, and application fields of airflow classifiers, we hope to help you better understand the value and role of this important equipment.

How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Selecting the right air classifier manufacturer is crucial for the quality of powder processing. Understanding the manufacturer's qualifications, product quality, and customer feedback ensures proper equipment configuration and maintenance, achieving optimal processing results. Let's explore how to find the best partners in the market!

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, the quality of powder materials is crucial. Airflow pulverizers, with their highly efficient pulverization capabilities and excellent particle uniformity, have become key equipment for improving powder quality. This article will delve into the working principles, advantages, and important applications of airflow pulverizers in powder production.

Comparative Analysis of Airflow Mills and Traditional Mills

For industries requiring high-efficiency and high-quality pulverization, air flow pulverizers are a better choice, while traditional pulverizers have their unique advantages in terms of applicability and economy. Understanding the differences between the two will help you choose pulverizing equipment more easily!

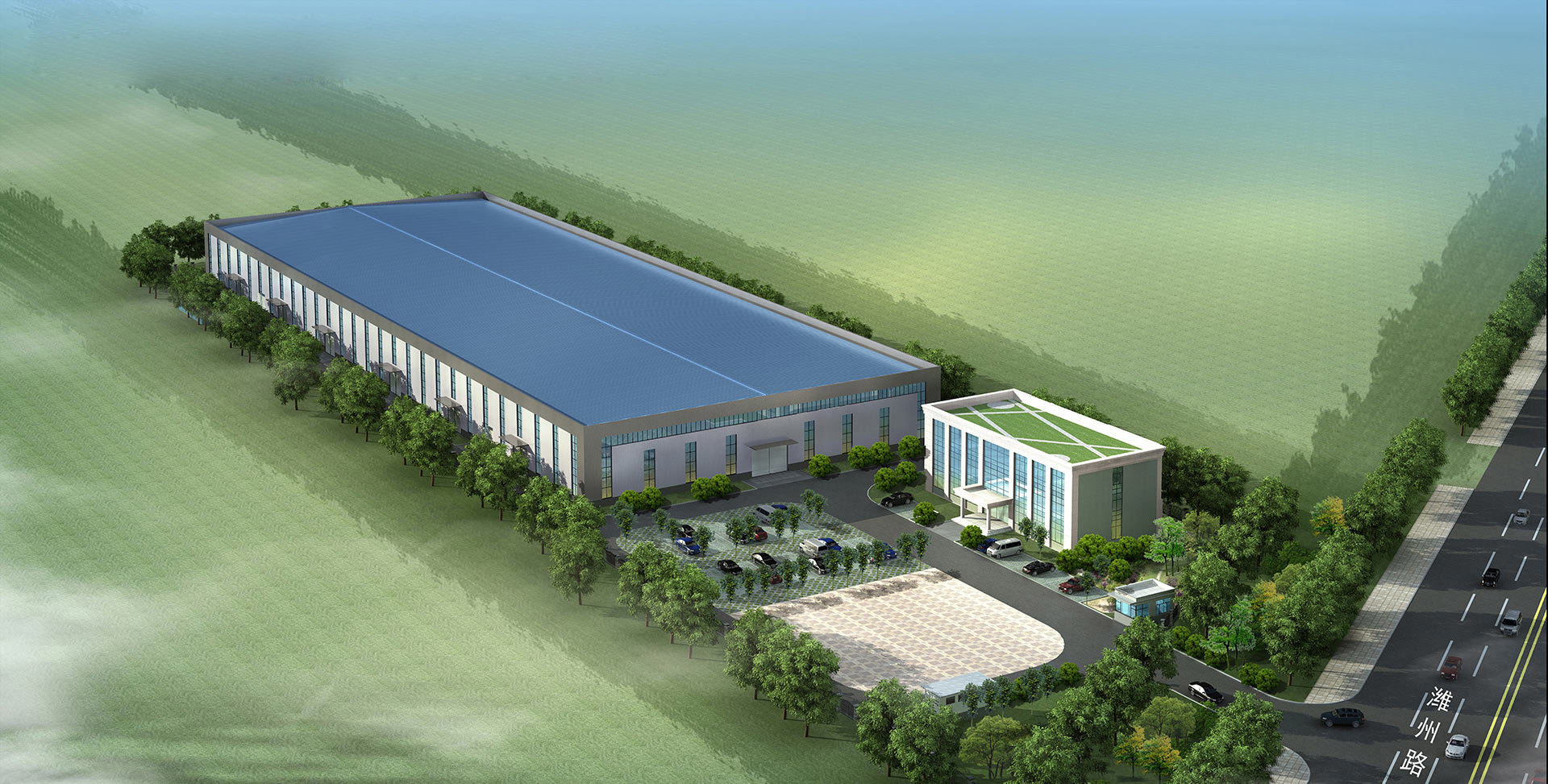

Shandong Jietemu Powder Technology Equipment Co., Ltd.

Address:500 meters northwest of the intersection of National Highway 206 and Beihai Road, Fangzi District, Weifang City, Shandong Province