Improving Powder Quality: The Importance of Airflow Pulverizers

Published Time:

2025-02-25 09:01

Source:

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, powdered materials are widely used in various fields such as chemicals, pharmaceuticals, and food. The quality of the powder directly affects the performance and effectiveness of the final product, so how to effectively improve powder quality has become a focus of many industries. Airflow pulverizers play a crucial role in this process. Today, let's talk about the importance of airflow pulverizers and how they help us improve powder quality.

What is an Airflow Pulverizer?

Before entering the world of airflow pulverizers, let's first understand its basic principles. An airflow pulverizer is a device that uses high-speed airflow to pulverize materials. In this process, the materials are propelled by the airflow, resulting in high-speed collisions, thus achieving fine particle size. Simply put, it's like a violent storm that pulverizes large chunks of material into fine powder.

Working Principle of Airflow Pulverizer

The working principle of an airflow pulverizer is actually quite simple. It uses compressed air or gas to generate high-speed airflow, which is fully mixed with the material in the pulverization chamber. Then, under the action of the high-speed airflow, the material undergoes collisions and friction, thereby achieving pulverization. This pulverization method not only results in uniform particle size but also effectively maintains the material's characteristics. It's like stir-frying in a hot pan; the more intense the heat, the more evenly cooked and flavorful the ingredients become.

Advantages of Airflow Pulverizers

There are many advantages to using airflow pulverizers. Today, I'll list a few for you:

1. High Particle Uniformity

After using an airflow pulverizer, the resulting powder particles are very uniform. This is particularly important for industries that require a specific particle size distribution. Imagine if you were making a new drug; uneven particle sizes would lead to unstable efficacy, which would be quite troublesome.

2. Maintaining Material Properties

During the airflow pulverization process, the temperature is relatively low, so it can effectively maintain the material's heat sensitivity and chemical properties. This is very important for many temperature-sensitive materials, especially in the pharmaceutical and food industries. Can you imagine how much the drug efficacy would be affected if the powder was heated during pulverization?

3. Wide Range of Applications

Airflow pulverizers are not only suitable for various high-hardness and brittle materials but can also easily handle some sticky materials. This versatile characteristic allows it to be widely used in many industries. Imagine it as a multi-purpose tool capable of handling various pulverization tasks.

Applications of Airflow Pulverizers in Improving Powder Quality

Let's return to the main topic: how exactly do airflow pulverizers play a role in improving powder quality?

1. Improved Production Efficiency

In powder production, production efficiency directly affects a company's output value. Airflow pulverizers can pulverize a large amount of material in a short time, greatly improving production efficiency. Imagine if a company could produce more products in the same amount of time; its competitiveness would naturally be greatly enhanced.

2. Fine-tuned Control

Airflow pulverizers can also adjust the fineness of pulverization according to different production needs. This fine-tuned control makes the production process more flexible, thus meeting the needs of different customers. It's no longer a one-size-fits-all approach but allows for adjustments based on customer preferences.

3. Reduced Production Costs

Finally, it's worth mentioning the advantage of airflow pulverizers in reducing production costs. By improving production efficiency and reducing energy consumption, companies can save a significant amount of production costs while maintaining product quality. As a result, profits naturally increase.

Summary

In general, the importance of airflow pulverizers in improving powder quality cannot be overlooked. It not only improves the uniformity of the powder, maintains the material's characteristics, but also brings companies higher production efficiency and lower costs. In a fiercely competitive market, mastering the core technology of airflow pulverizers is undoubtedly the key to winning the market.

In this rapidly developing era, how to improve powder quality is a problem that every industry needs to seriously consider. The existence of airflow pulverizers undoubtedly provides us with an effective solution. Hopefully, today's sharing will give you a deeper understanding of airflow pulverizers, and perhaps the next time you choose pulverizing equipment, you will consider the elegance and efficiency of airflow pulverizers.

Related News

How do air classifier manufacturers meet the needs of different industries?

This article reveals how air classifier manufacturers flexibly meet the needs of different industries, and explores the importance of technological innovation and customer communication. Let's focus on the future development of this field together, and choose the most suitable solution for your business.

Recommended manufacturers of the most popular airflow classifiers in the industry

When searching for airflow classifier manufacturers, it is crucial to understand the popular brands, technical capabilities, and after-sales service in the market. This article recommends some manufacturers worth your attention to help you make an informed choice.

Air classifier manufacturer reveals: Core technology of ultrafine powder processing

In this article, we reveal the core technologies of airflow classifier manufacturers and explore the mysteries of ultrafine powder processing. By gaining a deep understanding of the principles, key technologies, and application fields of airflow classifiers, we hope to help you better understand the value and role of this important equipment.

How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Selecting the right air classifier manufacturer is crucial for the quality of powder processing. Understanding the manufacturer's qualifications, product quality, and customer feedback ensures proper equipment configuration and maintenance, achieving optimal processing results. Let's explore how to find the best partners in the market!

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, the quality of powder materials is crucial. Airflow pulverizers, with their highly efficient pulverization capabilities and excellent particle uniformity, have become key equipment for improving powder quality. This article will delve into the working principles, advantages, and important applications of airflow pulverizers in powder production.

Comparative Analysis of Airflow Mills and Traditional Mills

For industries requiring high-efficiency and high-quality pulverization, air flow pulverizers are a better choice, while traditional pulverizers have their unique advantages in terms of applicability and economy. Understanding the differences between the two will help you choose pulverizing equipment more easily!

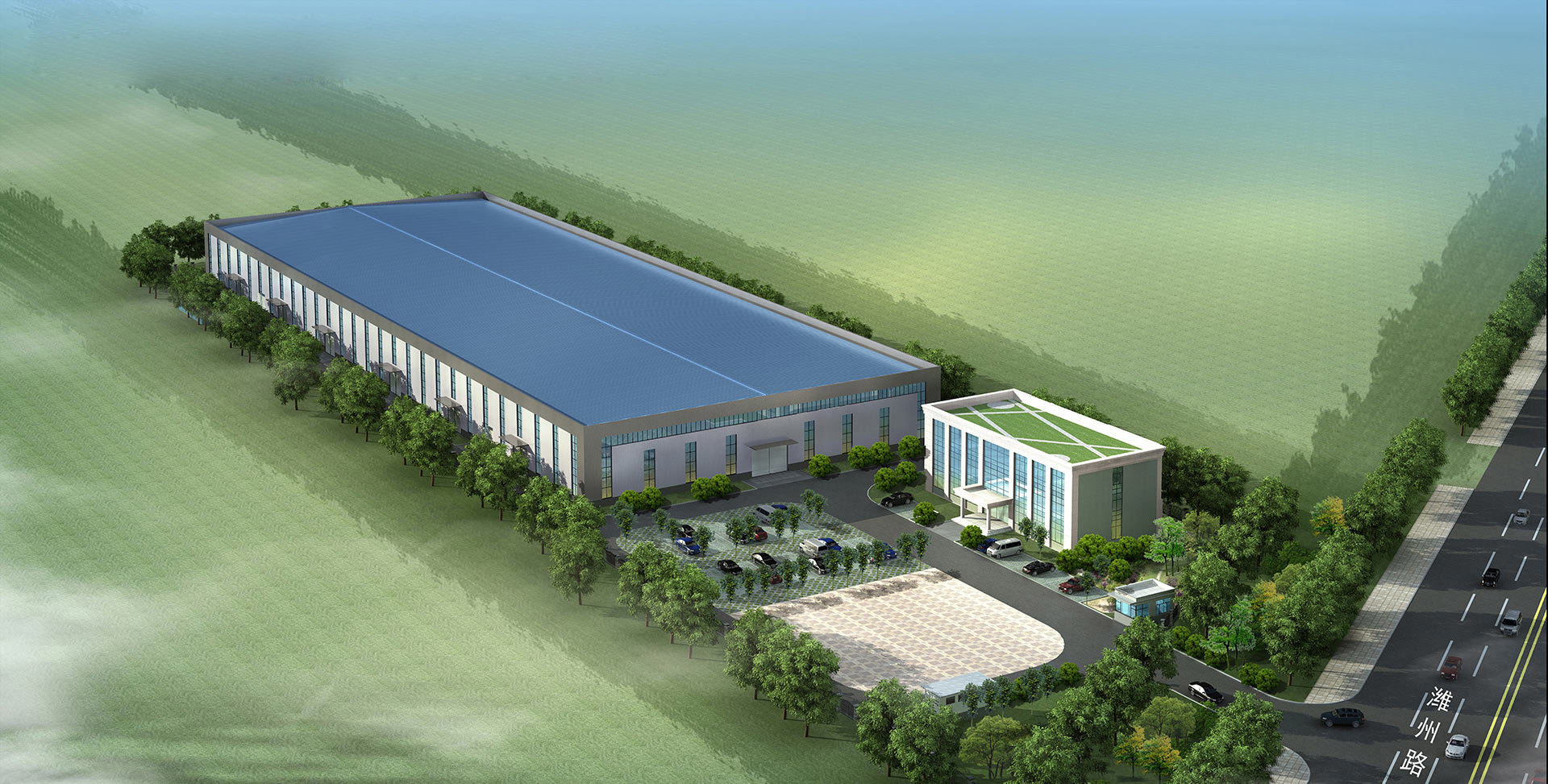

Shandong Jietemu Powder Technology Equipment Co., Ltd.

Address:500 meters northwest of the intersection of National Highway 206 and Beihai Road, Fangzi District, Weifang City, Shandong Province