Advantages and characteristics of airflow pulverizers and applications of ultrafine airflow pulverizers

Published Time:

2021-04-28 14:22

Source:

Related News

How do air classifier manufacturers meet the needs of different industries?

This article reveals how air classifier manufacturers flexibly meet the needs of different industries, and explores the importance of technological innovation and customer communication. Let's focus on the future development of this field together, and choose the most suitable solution for your business.

Recommended manufacturers of the most popular airflow classifiers in the industry

When searching for airflow classifier manufacturers, it is crucial to understand the popular brands, technical capabilities, and after-sales service in the market. This article recommends some manufacturers worth your attention to help you make an informed choice.

Air classifier manufacturer reveals: Core technology of ultrafine powder processing

In this article, we reveal the core technologies of airflow classifier manufacturers and explore the mysteries of ultrafine powder processing. By gaining a deep understanding of the principles, key technologies, and application fields of airflow classifiers, we hope to help you better understand the value and role of this important equipment.

How to ensure the quality of powder processing when choosing an air classifier manufacturer?

Selecting the right air classifier manufacturer is crucial for the quality of powder processing. Understanding the manufacturer's qualifications, product quality, and customer feedback ensures proper equipment configuration and maintenance, achieving optimal processing results. Let's explore how to find the best partners in the market!

Improving Powder Quality: The Importance of Airflow Pulverizers

In modern industry, the quality of powder materials is crucial. Airflow pulverizers, with their highly efficient pulverization capabilities and excellent particle uniformity, have become key equipment for improving powder quality. This article will delve into the working principles, advantages, and important applications of airflow pulverizers in powder production.

Comparative Analysis of Airflow Mills and Traditional Mills

For industries requiring high-efficiency and high-quality pulverization, air flow pulverizers are a better choice, while traditional pulverizers have their unique advantages in terms of applicability and economy. Understanding the differences between the two will help you choose pulverizing equipment more easily!

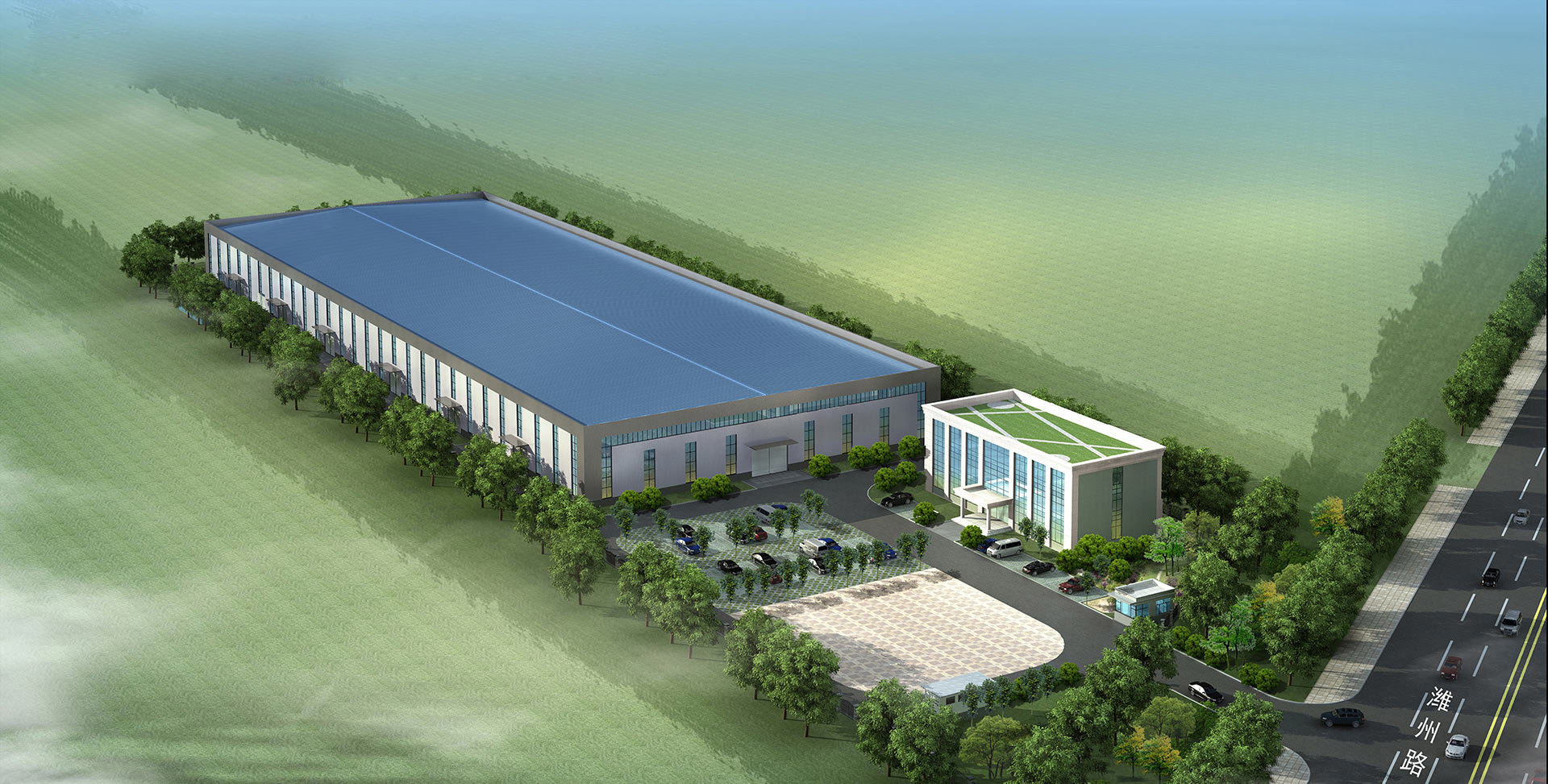

Shandong Jietemu Powder Technology Equipment Co., Ltd.

Address:500 meters northwest of the intersection of National Highway 206 and Beihai Road, Fangzi District, Weifang City, Shandong Province